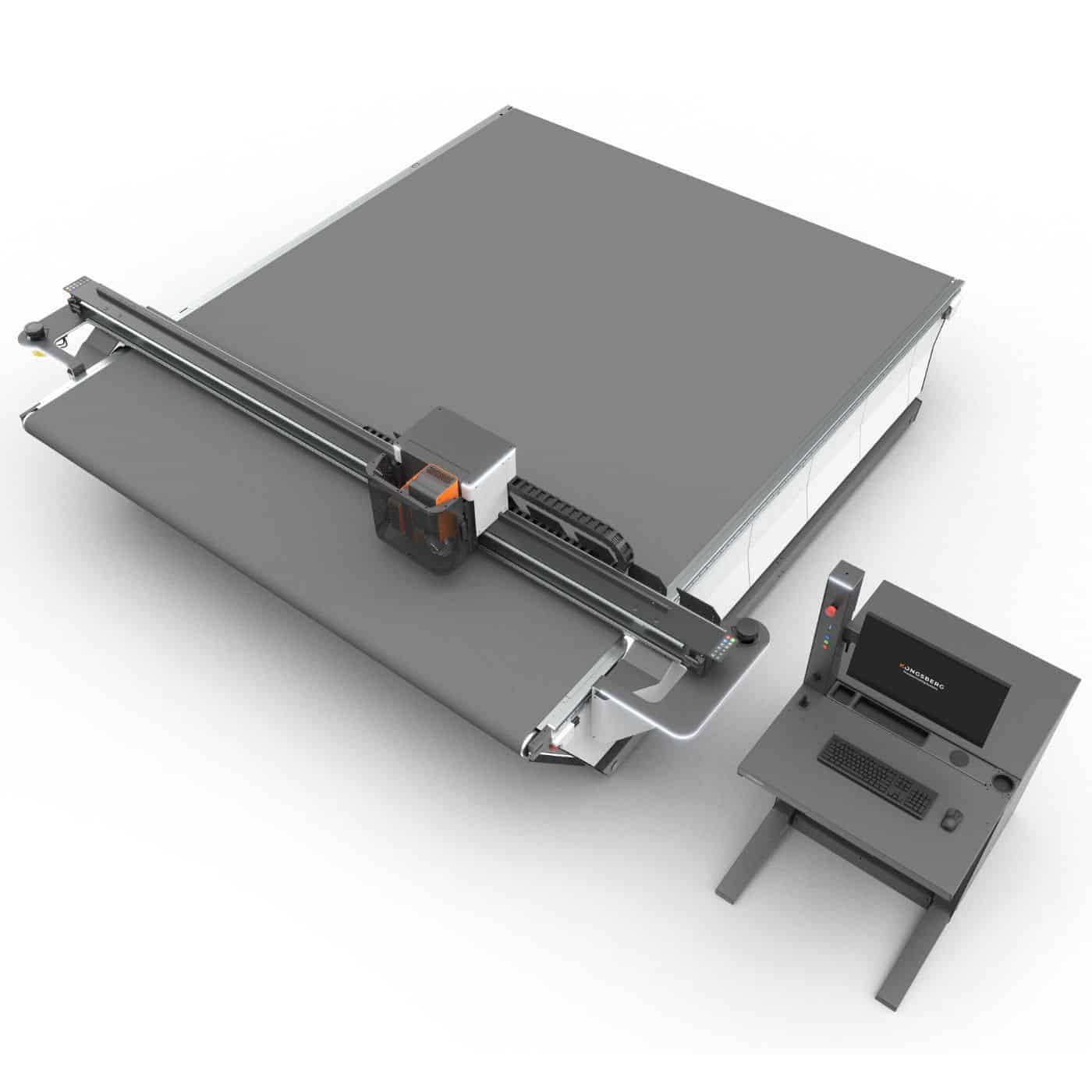

Kongsberg Ultimate Cutting Table

Engineered for High-Speed Corrugated Production

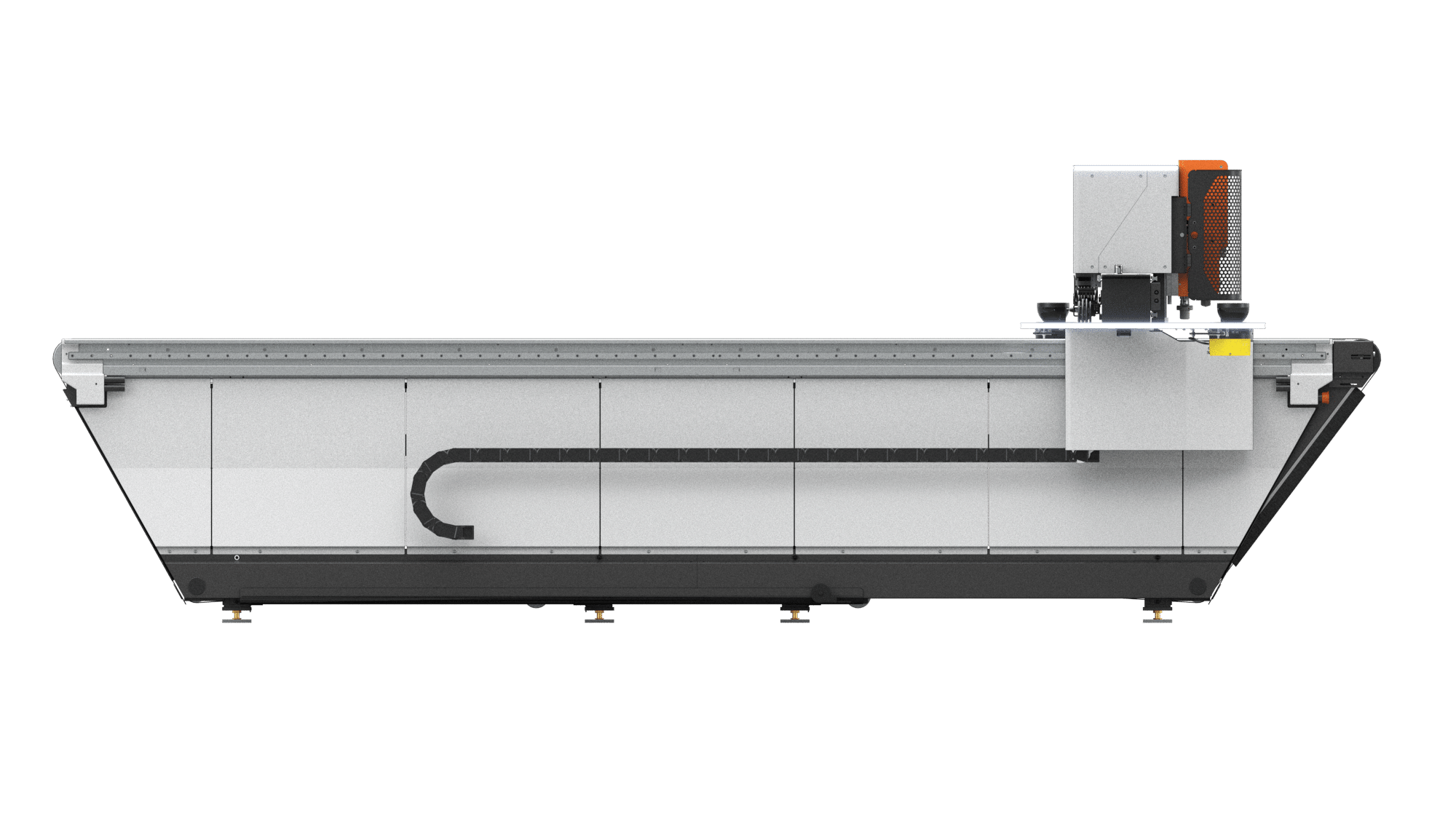

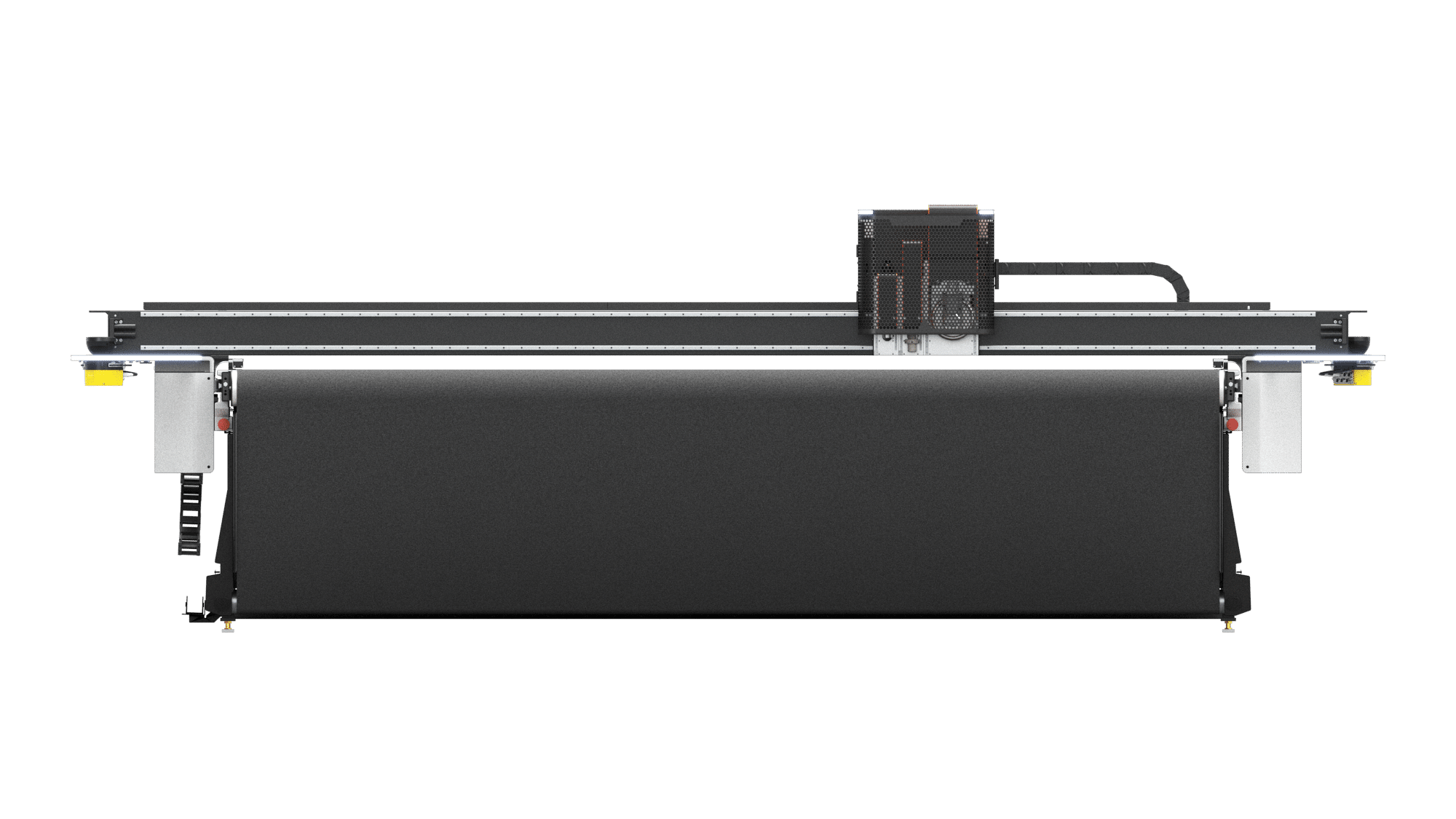

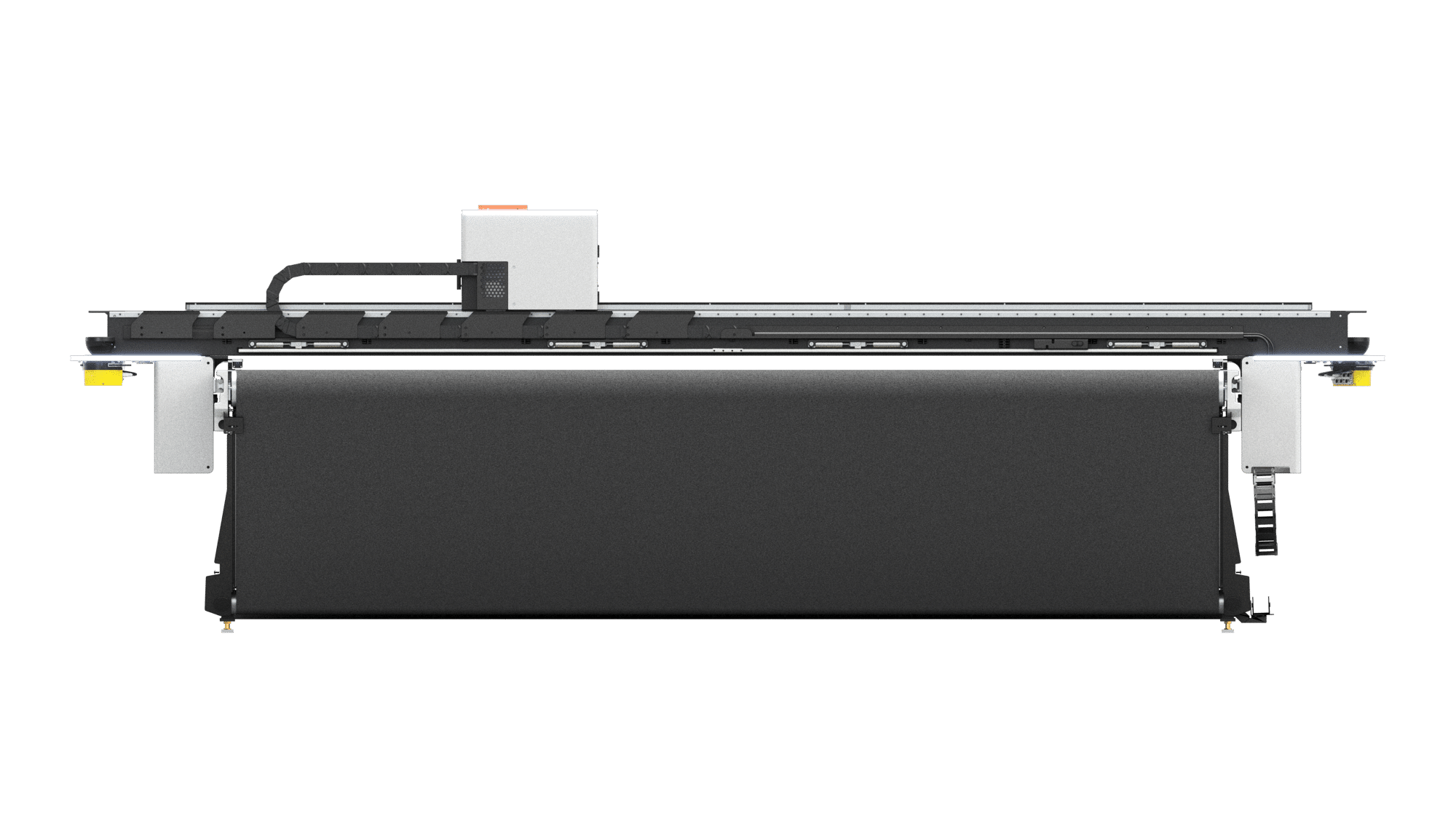

The Kongsberg Ultimate cutting table has been designed for high-volume corrugated and display applications. Productivity is maximised through intelligent automation. Acceleration of up to 2.7 G and speeds of 167.5 m/min are achieved using the in-house developed Kongsberg PrecisionDrive™ system.

Exceptional Precision, Built to Endure

A unique carbon fibre traverse reduces flex, delivering consistent 50 kg downforce across the table. This ensures precise creasing and V-notching on every pass. The steel frame guarantees stability during continuous production. The Kongsberg Ultimate cutting table delivers dependable results, even under the most demanding workloads.

Optimised Tooling and Workflow

Three tool positions allow creasing, cutting, perforating, and oscillating without tool changes. Workflow is streamlined with intelligent route sequencing. The tool head camera and LED lights automatically detect marks and edges, reducing manual intervention. MultiZone operation allows alternate zone loading for non-stop output.

Modular Automation for Future Growth

The modular platform enables flexible upgrades. Semi-automation is supported through Feeder & Stacker systems. Full automation can be achieved using a Robotic Material Handler. Minimal maintenance is required due to the gearbox-free design, reducing downtime and enhancing uptime.

Operator-Friendly and Sustainable

SmartZone™ safety slows or stops operation based on proximity, ensuring safe access. The intuitive iPC 3.0 interface enhances user control. Energy-efficient motors, recycled materials, and local sourcing support environmental goals. Every detail has been crafted with the user and sustainability in mind.

The Kongsberg Ultimate cutting table is a long-term investment built for fast, accurate, and high-volume digital finishing.

Footy Tips

Footy Tips